REPLICATION TOOLING AND UPSCALING OF YOUR STRUCTURES

HIGH PRECISION MOLDING

PRODUCTION OF NICKEL TOOLING

PRECISE REPLICA OF YOUR MICRO OR NANOSTRUCTURE

FROM A WAFER TO A NICKEL SHIM

You have originated a structure – visual, optical or functional – and need to replicate it for further processing? We can replicate your micro- or nanostructure from most wafers or molds and transfer them into a nickel shim (nickel plate). Our high precision nickel molding will let you have an exact copy of your master origination. Electroforming allows us to create as many duplicates of your original structure as you wish.

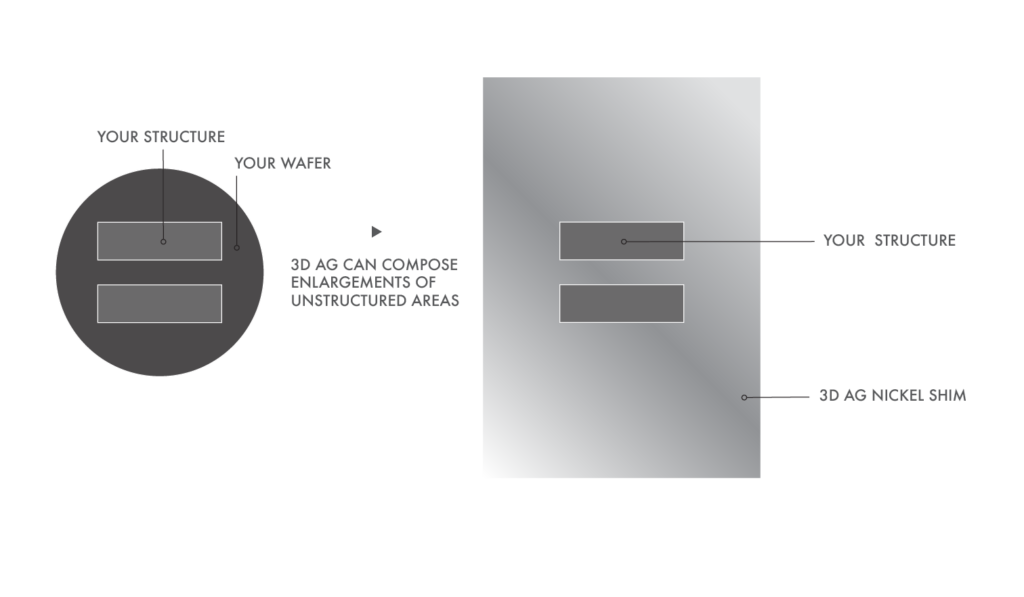

We create nickel shims (nickel plates), which are used widely in various industries as tool for molding or casting processes. Our nickel replica of your structure can be used for research purposes or as tool for mass replication. We can deliver different thicknesses and are also capable of enlarging the area around your structure in our replica, if the used wafer (master) has limited the space around your active structure area.

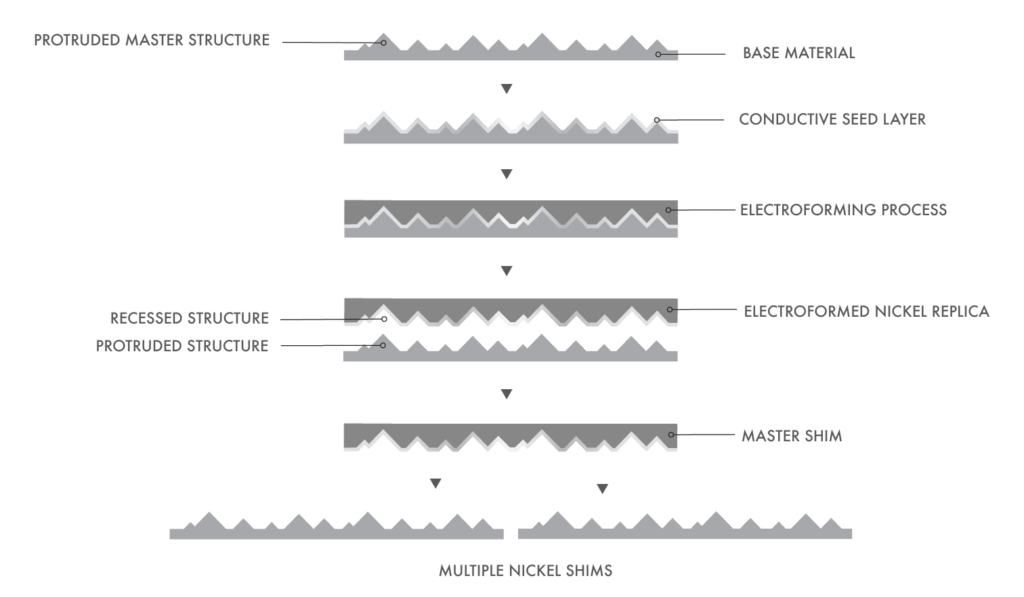

THE TECHNOLOGY: ELECTROFORMING

It is possible to generate a durable metal replicas from micro- and nanostructures with electroforming technology. 3D AG’s know-how and custom made galvanic baths allow us to create high precision nickel shim plates with our unique galvanic process.

Read our white paper!

SHIM SPECIFICATIONS

SIZE: Approx. 1200 mm x 1200 mm

THICKNESS: 25 µm up to cm

METAL PROPERTIES: Pure Nickel, hardness approx. 200 – 300 HV, weldable, no internal stress.

ADDITIONALLY WE CAN ENLARGE THE UNSTRUCTURED AREA!

UPSCALING OF YOUR STRUCTURE

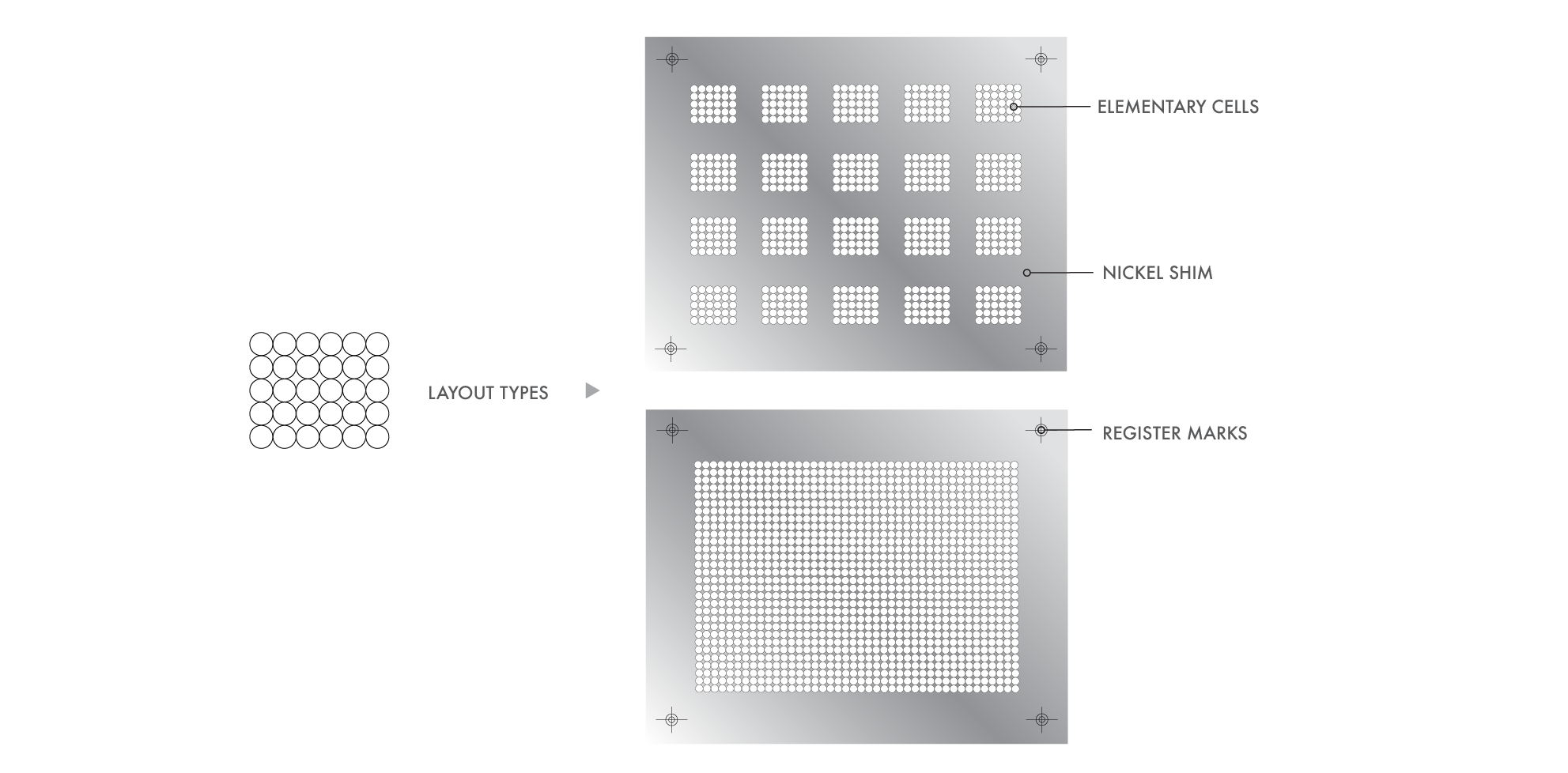

STEP AND REPEAT – UV RECOMBINATION

FROM LAB SIZE TO LARGE FORMAT

You create and develop structures in the lab, but are limited to a certain size? You are entering the commercial phase and need to enlarge your structured area or have a specific layout for production? Our UV recombination technology is a step and repeat process for upscaling your structured area in any specific layout.

We can create a layout according to your needs for further processing!

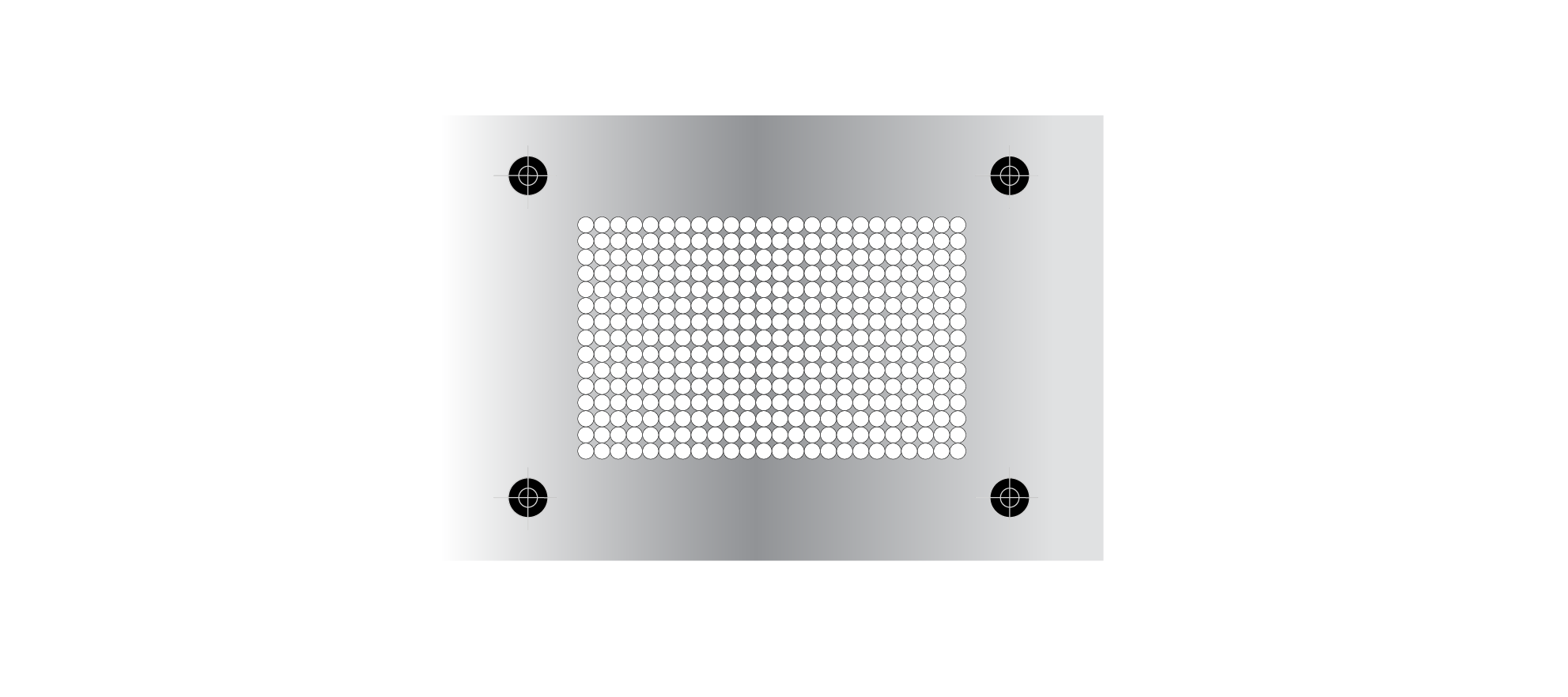

CUSTOMIZED LAYOUTS: WE CAN ADD REGISTER MARKS AND CUTTING LINES ACCORDING TO YOUR SPECIFIC LAYOUT AND FURTHER PRODUCTION STEPS

“3D AG combines science, technology and production with perfection – the Swiss way!”

PARTNER NETWORK: WE ALSO OFFER NICKEL SLEEVES!

FOR WHAT CAN YOU USE OUR SHIM TOOLS?

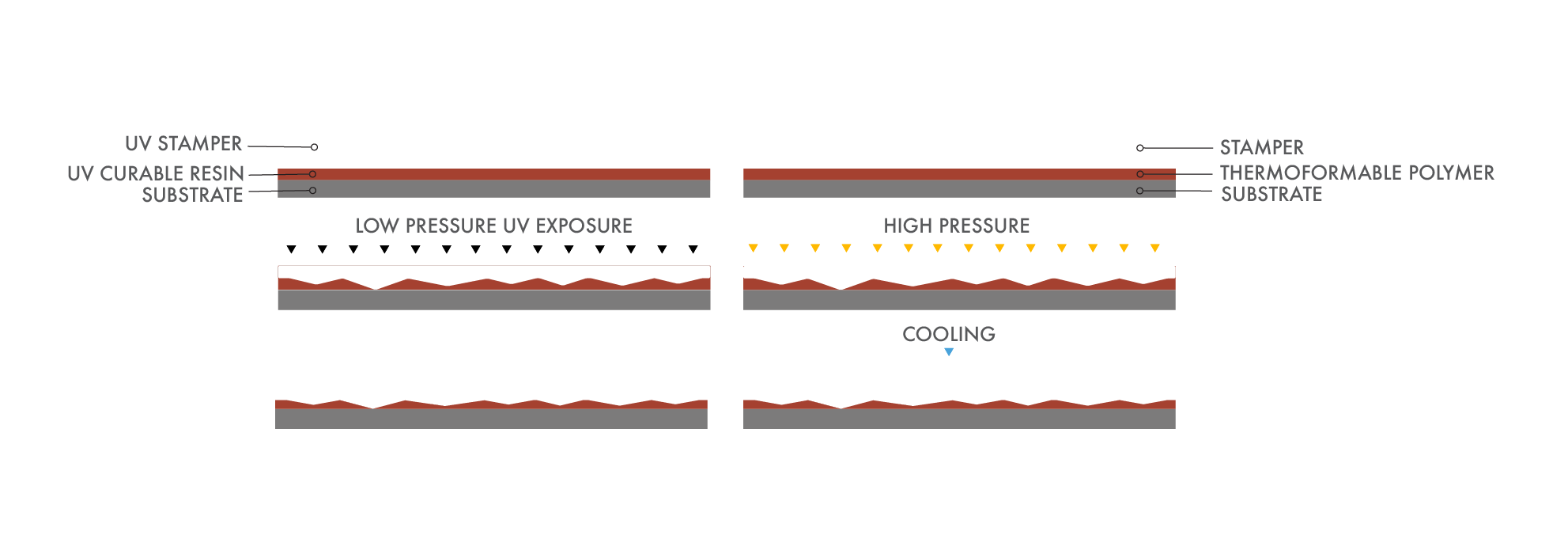

Possible Applications: Use our nickel shims for UV casting (UV embossing), UV curing, hot embossing, hard embossing, soft embossing, E-Beam curing, Injection molding, roll to roll embossing etc….

CONSULTING

A WORLD OF OPPORTUNITIES

Our experience and know-how gathered during the past years are an optimal base to discuss feasibility and options. Founded in 1989, 3D AG has acquired knowledge and skills in the broad field of micro- and nanotechnology.

We have witnessed and observed the changes and evolutions in the market from which we have gained our know-how, awareness and philosophy. Let our competent consulting guide you through this world of opportunities to find the best output for you.

“Strive not be a success, but rather to be of value.”

Albert Einstein

ABOUT US

SOLUTION DRIVEN

Founded in 1989 by Dr. David L.Greenaway †, as a technology center for holographic structures, the physicist and scientist Dr. Greenaway engaged into the fundamental research of holographic procedures for years. He played a leading role in the development and construction of the first holographic production facilities, finally allowing the mass production of the optical phenomenon holography.

Over the years 3D AG engaged into the perfection of electroforming. We have built various galvanic baths and mastered unique techniques of replication.

With this History, 3D AG’s experts started to explore and acquire knowledge of various functional surfaces, diving into the vast world of micro- and nanotechnology. Researching these different structures and the exposure to many new base materials and components has allowed us to consult our customers better. Our goal is to constantly improve our science, to become the best partner we can be.

CONTACT US

We’re open for new trends and put our whole soul into every project.

Every client is special, and every project is unique.

Contact us with any questions or remarks

© 2017 3D AG All Rights Reserved